In the food, medical, and high-tech industries, product quality is closely linked to package sealing. When oxygen enters the packaging, it can cause food oxidation and spoilage, as well as compromise the stability of medical devices and electronic products. To quickly check for package leaks, oxygen indicators (Oxygen Indicator) were developed, providing a reliable detection method. They can also be considered a type of smart packaging, using color changes to instantly show the presence of oxygen and help improve product quality control.

1.What is an Oxygen Indicator?

An oxygen indicator is a detection material that changes color to indicate the presence of oxygen. When the internal environment of a package remains oxygen-free, the indicator displays a specific color (pink). If oxygen penetrates the package, the color changes noticeably (blue-purple), allowing users to visually determine whether the seal is compromised.

Common types include:

- Adhesive Type: Can be attached directly to the product surface or used alongside oxygen scavengers.

- Single-sheet type: Placed inside the package, suitable for vacuum or nitrogen-flushed packaging.

2.Uses of Oxygen Indicators

Oxygen indicators have a wide range of applications, particularly in industries that require low-oxygen environments, and are highly effective for quality control.

- Food industry: Used in vacuum or nitrogen-flushed packaging to ensure seal integrity and prevent oxidation, discoloration, or rancidity of food products.

- Medical industry: Applied in monitoring medical devices, reagents, and consumables to ensure products remain unaffected by oxygen during storage.

- Industrial applications: Such as optical components, lenses, sensors, and electronic parts, where oxygen indicators help verify package integrity.

By observing color changes, companies can monitor oxygen intrusion during shipment, transportation, and storage.

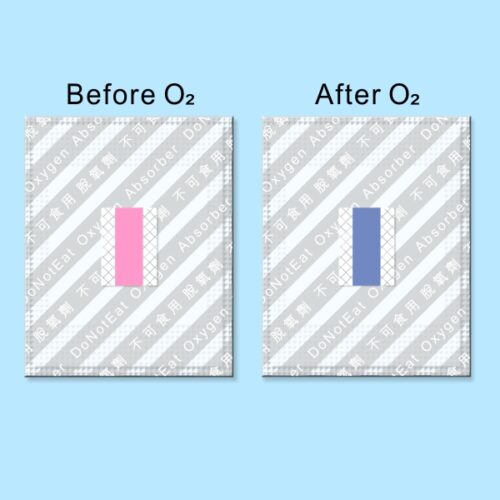

3.How Oxygen Indicators Work?

The color-changing principle of oxygen indicators is based on reducing dyes. In an oxygen-free environment, the indicator remains in its reduced state and displays a specific color (pink). When oxygen enters, an oxidation reaction occurs, turning the color to blue-purple.

This reversible color reaction is immediate and visual, enabling quick assessment of oxygen levels in the package without using instruments.

4.How to Use Oxygen Indicators?

- Prepare the indicator type (adhesive -type or single-sheet).

- Placement: Attach adhesive -type indicators to the product surface or on top of oxygen absorbers; place single-sheet indicators inside the package.

- After sealing the package, observe the color: if the color remains pink after six hours, the seal is intact; if it changes to blue-purple, the package may be compromised.

5.Storage and Handling of Oxygen Indicators

- Avoid high temperatures and direct sunlight.

- Store in a cool, dry place below 25°C, with a shelf life of approximately 20 days.

- Refrigeration at below 10°C can extend the shelf life to 30 days.

- After opening, please use within three hours to prevent the indicator paper from becoming ineffective due to prolonged exposure to oxygen.